Power to the People

Berlin leads the way in energy storage systems and battery-related business.

Our future depends on efficient battery technology without dependency on finite natural resources. Going electric sustainably, for example in mobility, will only work if we can store and distribute power easily at no cost to the environment. That’s why many Berlin institutes are investing time and money into the research and development of new technologies that will be an integral part of achieving climate neutrality and the goals set out in the Paris Accords. Industry and business carry a great responsibility in achieving climate neutrality, and Berlin is prepared to support all companies working towards achieving the aims.

The Place to Create the Future of Energy

Berlin has the highest density of research institutes in Europe, and many of these have a particularly high degree of competence in the fields of energy storage and manufacturing technologies. To name but a few well-known centers of scientific excellence, the Technical University Berlin (TU), the Fraunhofer Institute for Production Systems and Design Technology, and the Federal Institute of Materials Research and Testing (BAM) are available as cooperation partners for innovation projects. All told, 30,000 scientists in more than 30 research and development organisations are carrying out cutting edge research and development in various academic disciplines including battery technology in Berlin.

Being situated in the capital of one of Europe’s, indeed the world’s strongest economies has its benefits. Berlin is the center of decision-making in politics, industry and science, and is also the seat of major energy and mobility associations, national agencies, and representative offices of German and international utilities companies.

The young and well-educated population also means that there are plenty of human resources to draw on, with an estimated skilled workforce for battery-related operations of 126,000 people. Berlin higher education institutes have particularly high numbers of graduates in engineering faculties, with 12,000 students of battery-related subjects. The city of Berlin in cooperation with the German government is actively promoting the education and training of specialists for the specific field of battery-related technologies. On the other hand, fast track services for work and residence permits for foreigners make it easy to hire just the right person for the job.

The Battery Value Chain

Berlin has a grown ecosystem of companies directly involved in various parts of the battery production value chain. There are a number of companies dealing in stationary and mobile storage systems, electrode production, machinery for cell production, cell assembly, battery management systems (BMS), testing and validation, power electronics (i.e. the application of solid-state electronics to the control and conversion of electric power), and also recycling batteries.

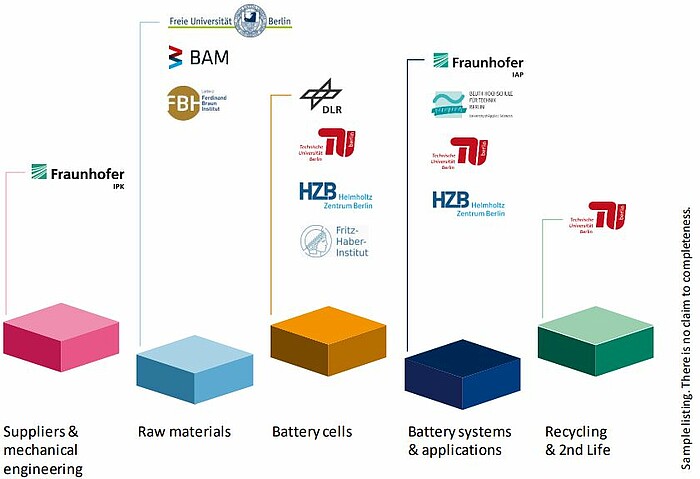

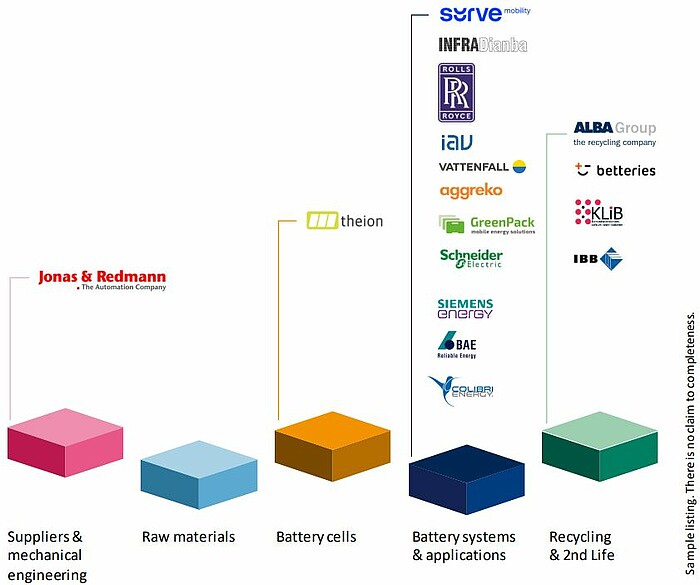

Suppliers and institutes researching aspects of the battery value chain include:

- raw materials – research projects at the Ferdinand Braun Institut and the Free University

- mechanical engineering – companies such as Jonas & Redmann and institutes such as Fraunhofer IPK

- battery cells – companies such as Theion (more on them here) and research at the Technical University, the DLR, and the Helmholtz Center

- battery systems & applications – companies such as Rolls Royce Solutions Berlin, Siemens energy, BAE, Swobbee, Schneider electric, and others; research at the TU, the Beuth University of Applied Sciences, and Fraunhofer

- recycling & 2nd Life – companies such as the Alba Group and betteries and research projects at the TU

Helping Ideas Gain Traction

Berlin is not only Germany‘s startup capital but also home to the highest density of incubators and accelerator programs. In the mobility and clean energy sector such programs support innovation by helping tech startups with mentoring, funding, marketing know-how, and connecting them with big industry.

The programs include InnoEnergy, techstars, Imagine2030, agile by eon, DB mindbox, EIT Climate-KIC and EIT RawMaterials, Hyundai Cradle, Volkswagen Ideation:Hub, Werner-von-Siemens Centre, and the Euref research campus.

Berlin-owned funding programs such as ProFIT and GRW Innovation Cluster were created to facilitate the transfer of academic research results to industrial applications in joint projects.

Driving Electric

Berlin has long been a pioneer in promoting electromobility. And now the industry is joining in. Mercedes is completely realigning its plant in Berlin-Marienfelde to boost digitization and electromobility. The company has set up a competence center for the digitalization of the global Mercedes-Benz production process in the Digital Factory Campus Berlin. This is to be the home of “MO360”, the digital Mercedes-Benz ecosystem integral to future production processes. Berlin will be training and qualification hub for all Mercedes-Benz plants worldwide. The Marienfelde plant itself, in which Industry 4.0 applications are in use already, will be a smart factory not only for the assembly of e-mobility components for all-electric Mercedes models, but also for the assembly of the so-called EE-compartment for the intelligent integration of power electronics for the cars’ battery systems.

The other famous smart automobile factory in the region is, of course, Tesla. The new European “Gigafactory” will be complemented by a battery plant. Elon Musk’s company is investing a reported 11 billion US dollars and will receive up to 1.6 billion in government subsidies for the creation of at least 14,000 new jobs. The fact that the American company chose the German capital region over other major cities for its European base speaks volumes. "Berlin rocks," said Elon Musk. Read more about Teslas new plant on Reason-why Berlin.

Such large projects have encouraged further investment from international companies operating in the battery industry such as Microvast, BASF or 50 Hertz Transmission, enhancing Berlin-Brandenburg as a prime location for the battery value chain.

Space to grow

There are dozens of places in which to settle. For instance, the Cleantech Business Park in Berlin’s Marzahn-Hellersdorf borough offers 90 hectares of well-connected space. Being dedicated to manufacturing companies specialized in sustainable and efficient technologies, it has a focus on low-emissions future tech. The former city airport Berlin TXL is turning into the Urban Tech Republic science and companies hub, the key location for future clean and urban technologies geared towards green energy production and storage, energy efficiency, sustainable mobility, recycling and new materials, with allocations beginning soon. Or read our article on the huge Adlershof business park, Germany’s largest science and technology park for research intensive industries and home to 1,200 hi-tech companies and 7,000 students at 17 research institutes. These are “future spaces” for all relevant actors: startups, scientific institutions, technology centers, SMEs, and established corporations.

Energy Technologies as well as Transport, Mobility, and Logistics are two main innovation clusters for Berlin’s economic development representing a total of approximately 16,000 companies with about 282,000 employees, with another important sector being manufacturing industries.

Dedicated interdisciplinary teams provide business and technology support for companies, investors and scientific institutions in Berlin, pushing cooperation projects forward. Berlin Partner offers concrete help in all aspects of settling and expansion, including finding office or production space, recruiting, or providing access to ecosystems or funding. In this way the city encourages and promotes investment both in battery cell production and in processes in the entire battery value chain.

Berlin is set to become Europe’s leading battery city, providing sustainable solutions to world problems.

Text: Olaf Bryan Wielk, ideenmanufaktur

Header image: © petrmalinak at Shutterstock